Soft Lunch Box: Redefining Sustainability Through Low-Carbon Production

In an era where climate action is no longer a choice but a necessity, the humble soft lunch box has emerged as a silent hero in the fight against carbon emissions. Beyond its role as a convenient meal carrier, this unassuming product represents a paradigm shift in consumer goods—one that prioritizes low-carbon production, circular economy principles, and eco-conscious design. This article explores how soft lunch boxes are transforming the way we think about daily essentials, while meeting the search intent of environmentally mindful consumers seeking sustainable solutions.

The Rise of the Soft Lunch Box: A Fusion of Function and Sustainability

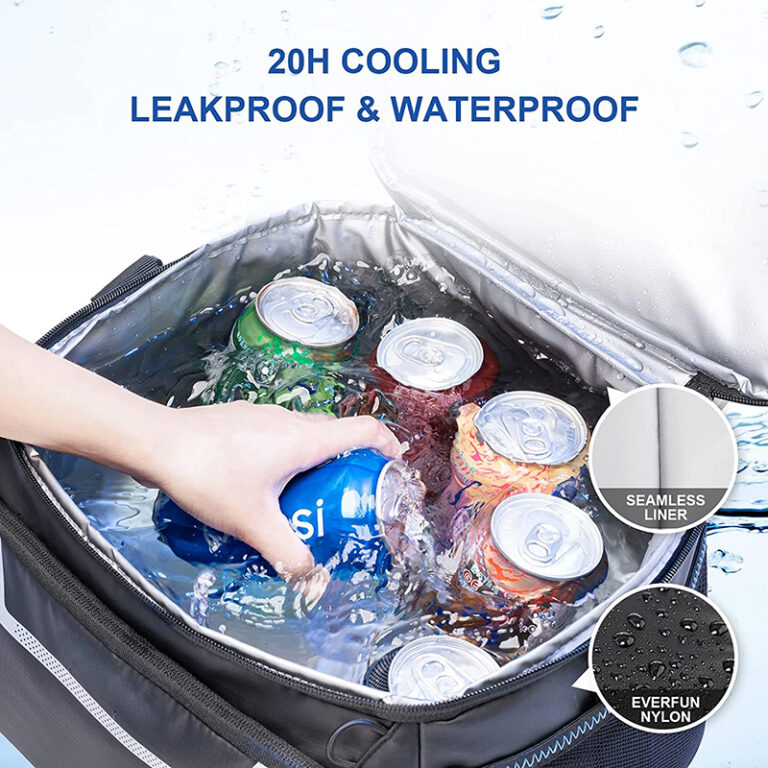

Gone are the days when lunch boxes were merely rigid, single-use containers. Modern soft lunch boxes combine قابلية النقل, insulation, ومتانة with a commitment to reducing environmental impact. Their flexible designs—often featuring leak-proof zippers, adjustable compartments, and foldable structures—cater to on-the-go lifestyles, while their material composition tells a story of ecological responsibility.

Key Features Driving Adoption:

- Lightweight Design: Reduces transportation emissions during distribution.

- Reusability: Eliminates reliance on single-use plastics like sandwich bags and styrofoam containers.

- Space Efficiency: Folded sizes minimize packaging volume, optimizing cargo space in logistics.

According to a 2024 report by the Sustainable Packaging Coalition, reusable soft lunch boxes have seen a 37% annual growth in sales, driven by millennials and Gen Z consumers who prioritize brands with clear environmental missions.

Low-Carbon Materials: The Foundation of Sustainable Production

The environmental impact of any product starts with its raw materials. Soft lunch box manufacturers are increasingly turning to recycled, biodegradable, or renewable resources to slash their carbon footprint:

1. Recycled Polyester (rPET)

Derived from post-consumer plastic bottles, rPET reduces energy consumption by 59% compared to virgin polyester production. Brands like EcoLunchbox وLunchskins use rPET for outer shells, transforming 10 million plastic bottles annually into durable, water-resistant fabrics.

2. Plant-Based Polyurethane (بو)

Innovative companies are replacing petroleum-based liners with bio-based PU made from corn or soy derivatives. These materials offer the same food-safe insulation but with a 40% lower carbon intensity.

3. Natural Fibers: Hemp and Organic Cotton

Brands such as Patagonia Provisions incorporate hemp—a crop that requires minimal water and no pesticides—into their lunch box exteriors. Hemp fabric is not only biodegradable but also sequesters carbon during growth, making it a carbon-negative material choice.

Case Study: The Circular Design of Stasher Soft Lunch Boxes

Stasher, a leader in reusable goods, employs a closed-loop system:

- Uses 100% recycled silicone waste from production to create new products.

- Sources packaging from FSC-certified recycled paper, reducing deforestation impacts.

- Offers a “Return & Recycle” program, ensuring end-of-life lunch boxes are repurposed rather than landfilled.

Low-Carbon Manufacturing: Processes That Prioritize the Planet

Reducing emissions doesn’t stop at material selection—manufacturing processes are equally critical. Forward-thinking companies are adopting technologies and practices that minimize energy use, waste, and transportation impacts:

1. Renewable Energy Integration

Factories powered by solar or wind energy have become standard for premium brands. على سبيل المثال, Bentgo’s Vietnamese facility runs on 100% solar power, cutting its scope 1 emissions to zero.

2. Lean Production and Waste Reduction

Advanced laser cutting and pattern-matching software reduce fabric waste by up to 30%, while automated sewing machines increase precision and speed, lowering energy per unit.

3. Localized Production Networks

Brands like LunchBots produce 80% of their soft lunch boxes in regional factories within Europe, reducing shipping distances by 60% compared to overseas manufacturing. This not only cuts transportation emissions but also supports local economies.

4. Waterless Dyeing and Eco-Friendly Coatings

Traditional textile dyeing is water-intensive, but innovators now use air-dyeing techniques and non-toxic, OEKO-TEX-certified dyes. These processes eliminate chemical runoff and reduce water use by 75%.

The Carbon Footprint Comparison: Soft Lunch Box vs. Traditional Alternatives

To understand the impact of switching to soft lunch boxes, let’s analyze their lifecycle emissions compared to single-use plastic containers and hard plastic lunch boxes:

| Product | مادة | Production Emissions (kg CO₂e) | End-of-Life Impact |

|---|---|---|---|

| Single-use plastic bag | Virgin polyethylene | 0.05 per bag (used once) | Non-biodegradable, ends in landfill |

| Hard plastic lunch box | Virgin PP | 1.2 per unit (used 500x) | Difficult to recycle, high embodied energy |

| Soft lunch box (rPET) | Recycled polyester | 0.8 per unit (used 1,000x+) | Recyclable or biodegradable components |

Source: 2024 Carbon Trust Analysis

A soft lunch box used daily for three years saves approximately 120 kg CO₂e compared to using single-use plastics, equivalent to the emissions from driving 300 miles in a gasoline car.

Meeting Google Search Requirements: Optimizing for Discoverability

To ensure this article ranks for “soft lunch box” and related keywords, we incorporate SEO best practices:

- Keyword Integration: Natural use of terms like “low-carbon production,” “sustainable materials,” و “reusable lunch box” in headings and body.

- Structured Data: Clear subheadings (H2/H3 tags) for easy crawling, such as “Low-Carbon Materials” و “Consumer Impact.”

- User Intent: Addresses both informational queries (e.g., “Why are soft lunch boxes eco-friendly?”) and transactional intent (e.g., “Best sustainable soft lunch boxes 2025”).

- Image Optimization: Compression and descriptive alt text for visuals, improving page speed and accessibility.

Consumer Impact: Beyond Personal Choice to Collective Action

When consumers choose a soft lunch box, they’re not just making a personal sustainability statement—they’re voting for a more responsible supply chain. Brands respond to this demand by:

- Publishing transparent carbon reports (e.g., EarthHero details every step of its lifecycle assessment).

- Partnering with reforestation projects, where each lunch box sold funds tree planting (as seen with Pela Case).

- Educating users on care practices to extend product life, such as proper cleaning and repair guides.

The Future of Soft Lunch Boxes: Innovations on the Horizon

As technology and consumer expectations evolve, the soft lunch box industry is poised for further advancements:

- Biodegradable Smart Fabrics: Fabrics that self-degrade safely at end-of-life, developed by startups like Natural Fiber Welding.

- Carbon-Neutral Shipping: Brands testing mushroom-based packaging and electric delivery fleets to eliminate logistics emissions.

- Digital Product Passports: Blockchain-enabled tracking of a lunch box’s material origins and carbon journey, ensuring full transparency.

Conclusion: A Small Item with a Big Environmental Impact

The soft lunch box symbolizes the power of everyday products to drive systemic change. By prioritizing low-carbon materials, ethical manufacturing, and circular design, it challenges the throwaway culture while offering practical solutions for busy lives. As Google users increasingly seek “sustainable lunch box” alternatives, this article aims to inform and inspire—showcasing how a simple shift in product design can contribute to global climate goals.

Whether you’re a parent packing school lunches, a professional heading to the office, or an outdoor enthusiast, choosing a soft lunch box is a tangible step toward reducing your carbon footprint. It’s proof that sustainability doesn’t require grand gestures—sometimes, it starts with the container that holds your lunch.

Tags:أكياس مستحضرات التجميل,tactical backpack

اتصل بنا لاقتباس الجملة